APPLICATION

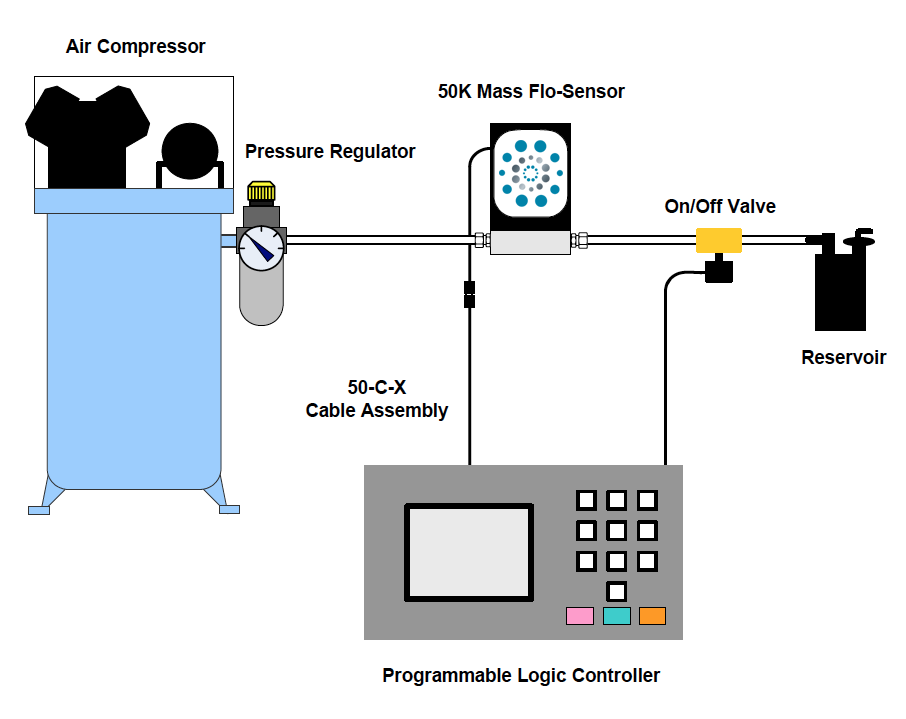

A plastic injection molding company supplies reservoirs to a car manufacturer. The reservoirs are an integral part of the evaporative emissions system and have to pass multiple quality control tests. One station will perform a flow test to verify that the reservoir is free of internal blockage. The test stand will require an output signal for automation and data acquisition.

MCMILLAN PRODUCTS UTILIZED

50K-10-E-A6-G0 Thermal Mass FLO-SENSOR

50-C-X Mating Cable

DESCRIPTION

McMillan Model 50K Thermal Mass FLO-SENSOR provides an analog output signal which is proportional to the flow rate. The maximum pressure rating is 150 PSIG. The Mating Cable with pigtail ends is connected to the power supply and programmable logic controller (PLC).

OPERATION

Regulated dry air (1-2 PSIG) flows through the Model 50K and reservoir to the atmosphere. A PLC monitors the 0-5 VDC output signal. A voltage signal of less than 3.5 VDC (7 Lpm) indicates an internal obstruction, and the defective piece is discarded. If the flow rate is above 7 Lpm the reservoir is moved to the next station for additional tests that do not make use of the Model 50K.

ADVANTAGES

McMillan Company’s patented thermal mass design provides accurate repeatable results with minimal zero drift. Metal construction, compact size and reasonable price make the Model 50K an ideal choice for this customer’s needs. Units are available with NIST-Traceable calibration. McMillan Company also offers a recalibration service. Custom configurations are available to OEM customers.

DIAGRAM

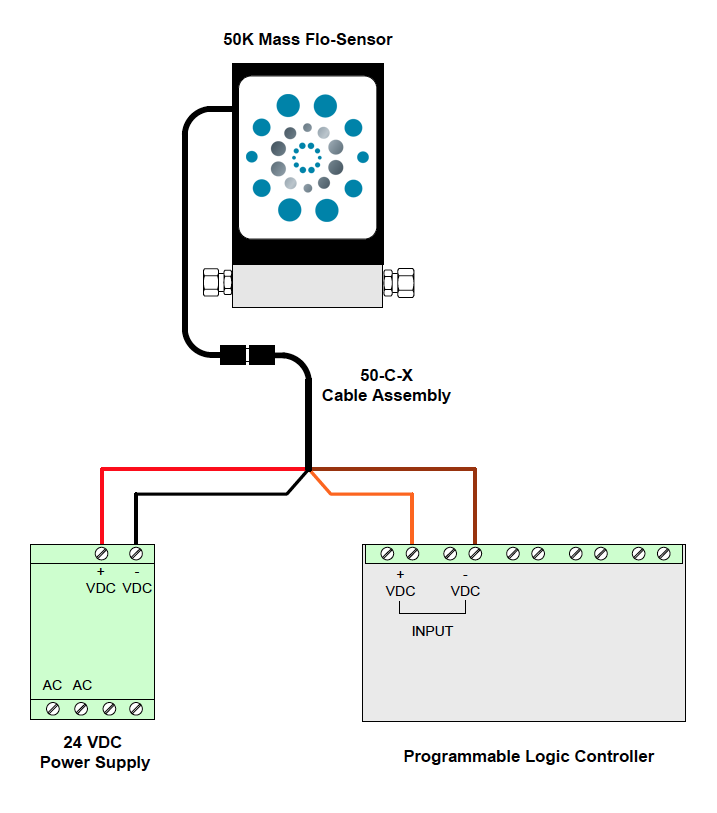

Figure 1 illustrates the flow path of the fluid system. Figure 2 illustrates the wiring of the system.

FIGURE 2 – System Wiring