APPLICATION

A semiconductor production facility uses a particle counter to monitor the quality of their deionized water. The particle counter requires a continuous flow rate of 60 mLpm. Visual indicators of flow and operating mode are needed. Future design and expansion of the facility will include recording the output from the flow controller by a data logging system.

MCMILLAN PRODUCTS UTILIZED

U801-3-C-F4-C10-P40 Liquid FLO-CONTROLLER

DESCRIPTION

McMillan Liquid FLO-CONTROLLERS combine smart electronics with a precision control valve and flow sensor. The output from the flow sensor is analyzed and compared to the flow rate set point. The control valve is then automatically adjusted to achieve the required flow.

OPERATION

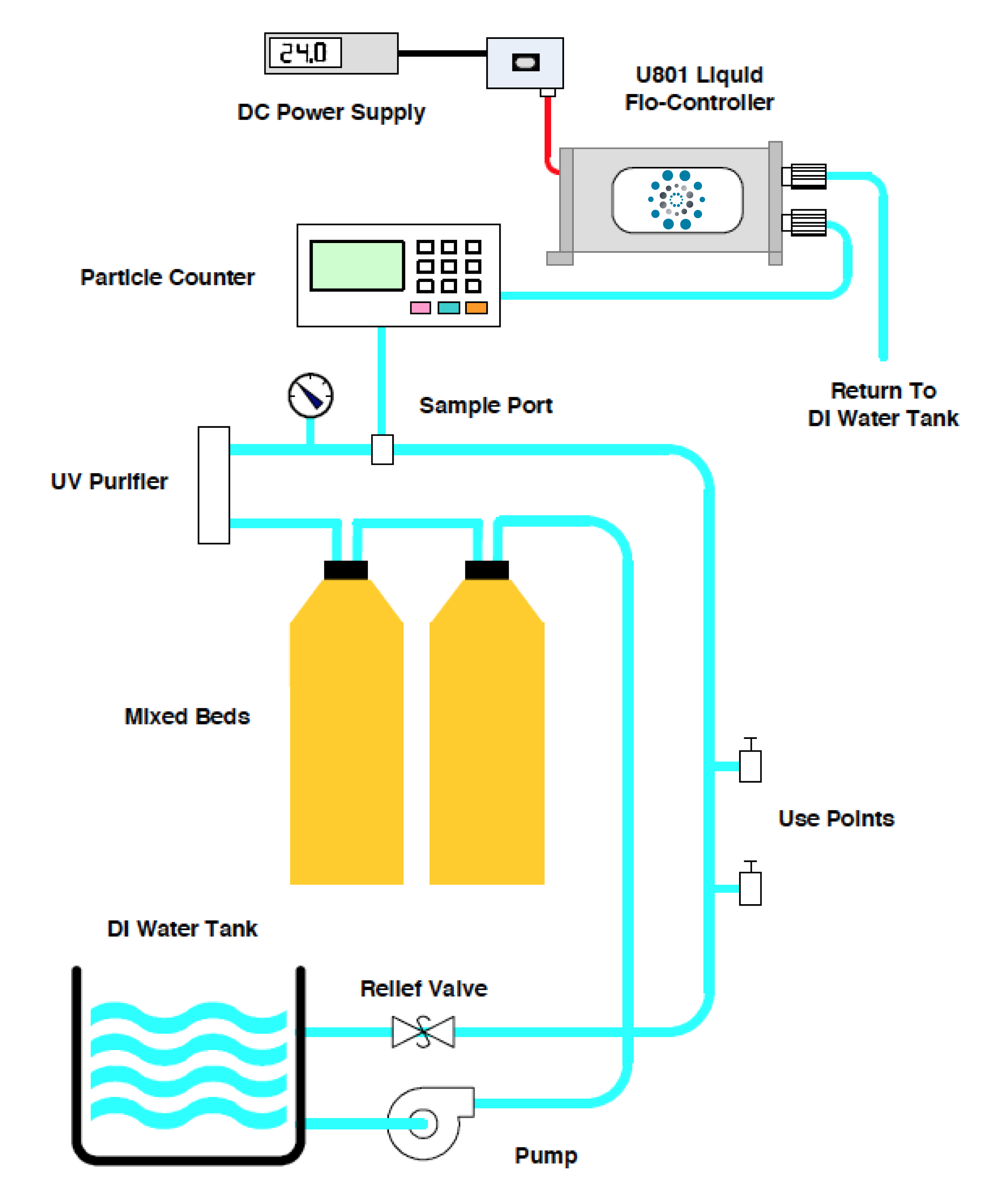

A sample of DI water flows through the particle counter, Model U801, then returns to the tank. The U801 operates as a stand-alone system using the internal setpoint for control and is powered by a DC power supply. The display on the control module shows the realtime flow rate in mA, LED indicators confirm normal operation, error mode and standby mode.

ADVANTAGES

Model U801 Liquid Flo-Controllers provide consistent flow regardless of small pressure changes and can be configured for available system pressure*. DIP switches on the control module allow the user to view flow or setpoint, choose internal or external setpoint and manually enter standby mode. Operation can be supervised remotely by monitoring the output signal, proportional to the flow rate. The error relay option includes a SPDT relay that is activated when an error is detected. Wetted materials are compatible with DI water and other chemicals. The benefits include an accurate, repeatable flow rate for the particle counter backed by years of reliable service and life expectancy of the Model U801.

DIAGRAM

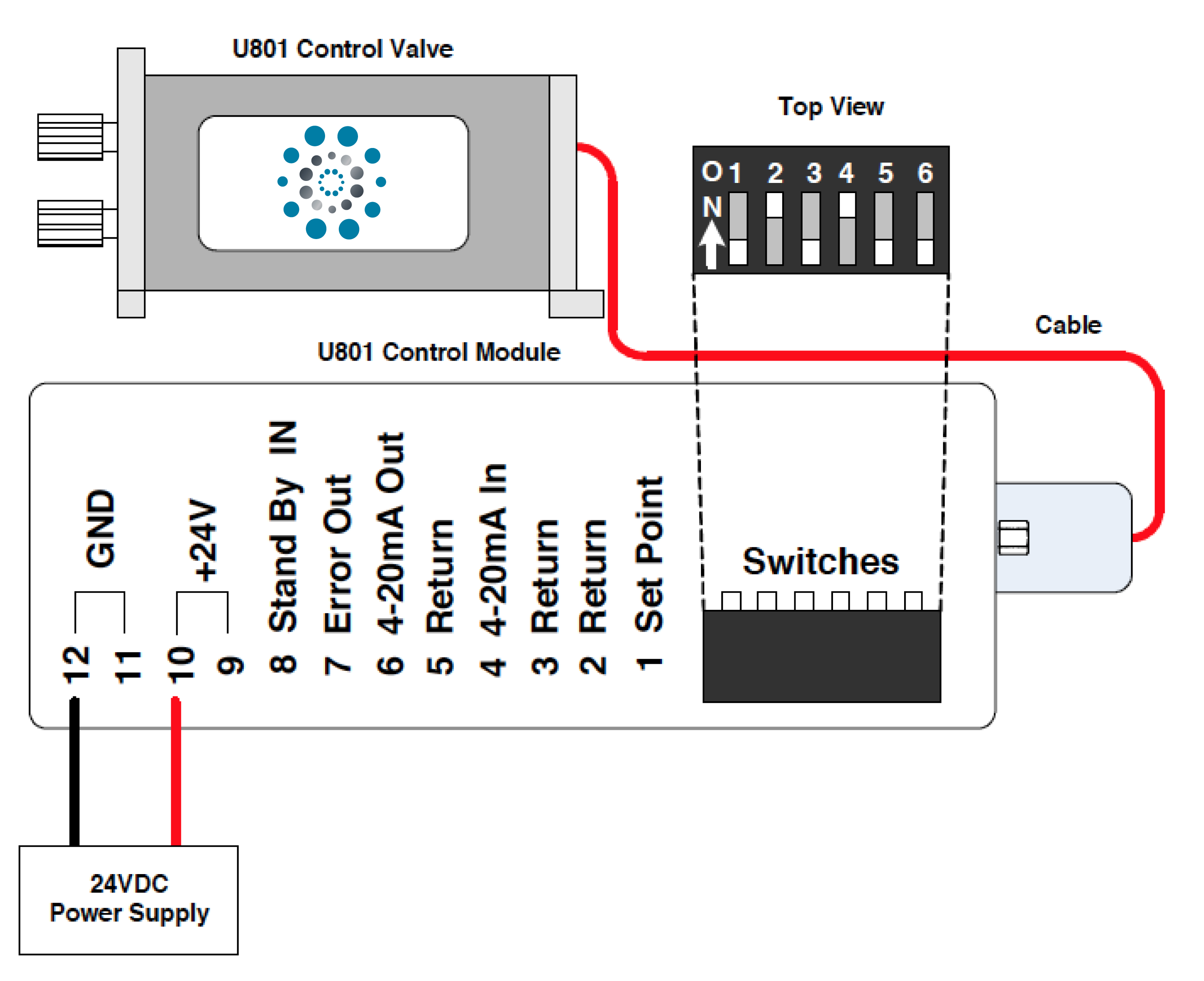

Figure 1 illustrates the flow path of the fluid system. Figure 2 illustrates the wiring of the system.

FIGURE 1 – Flow Path of Fluid System

FIGURE 2 – System Wiring