The Model U802 Ultra-High-Purity (UHP) FLO-CONTROLLER will precisely measure and control flow rates of virtually any fluid as low as 15 mL/minute or as high as 10 LPM. Repeatable results are achieved by utilizing a patented microturbine flow sensor design. This controller integrates all electronics and fluid components into a single package, eliminating the need for any external modules.

The Model U802 UHP FLO-CONTROLLER integrates a proportional double-diaphragm valve to accurately control flow rate. McMillan design insures long life expectancy under normal operating conditions – millions of cycles with no valve degradation.

±1.0% full-scale accuracy (including linearity & hysteresis) provides the critical control required for modern microelectronic applications. Unparalleled repeatability reassures process engineers that results will be consistent.

An optional temperature rating of 0-90°C allows use in most UHP applications.

Model U802 Features & Options

AACCURACY/LINEARITY

All models have an accuracy specification of ±1.0% full scale (including linearity).

CALIBRATION

All units are calibrated at the factory using deionized water. Calibration curves may be requested for fluids with viscosities differing from water.

DISPLAYS

An external control module is available that displays current settings, programs special features and options, and allows for calibration adjustments. Please request further information from the factory.

ELECTRICAL CONNECTIONS

All units have an integrated 7-pin connector. Several mating cable options are available. An additional 12-pin connector is fitted for custom configurations and factory programming.

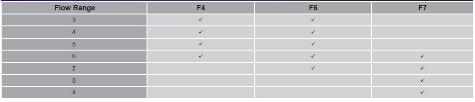

FLOW RANGES

Flow ranges from 15-100 mL/minute up to 1,000-10,000 mL/minute are available. Consult factory for custom requirements.

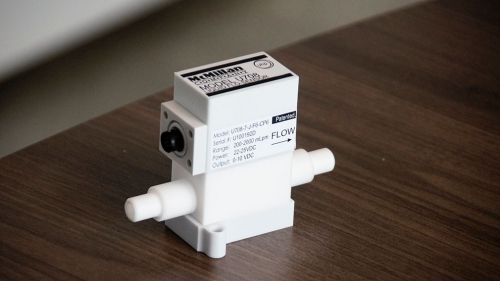

FLUID CONNECTIONS

All units have male Flaretek-compatible connections. Non-standard connection types may be available upon request.

POWER

Units operate with 24 VDC power.

SIGNAL CONFIGURATION

Units may be ordered with a 4-20 mA, 0-5 VDC, or 0-10 VDC configuration.

WETTED MATERIALS

All units have only PTFE, perfluoroelastomers, and sapphire as wetted parts.

Fitting Chart

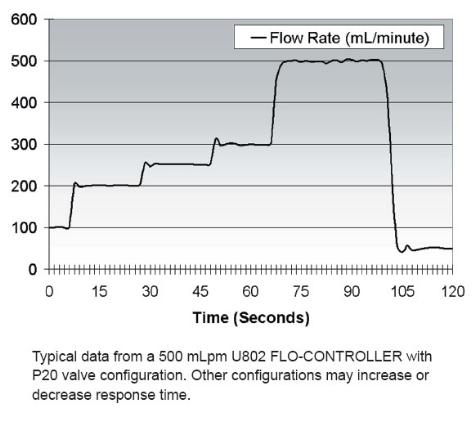

Typical Response Time

Specifications

- Accuracy (including linearity, best fit straight line):

- ±1.0% Full Scale

- Repeatability:

- ±0.20% Full Scale

- Pressure Rating:

- 80 psig (5.4 bar) maximum working

100 psig (6.8 bar) overpressure - Temperature Rating (Fluid):

- Standard: 0 to 55ºC

HT Suffix: 0 to 90°C - Temperature Rating (Environment):

- Operating: 0 to 50ºC

Storage: 0 to 70ºC - Valve Type:

- PTFE cam-driven diaphragm

Not recommended for positive shutoff - Wetted Materials:

- PTFE

Sapphire - Exterior Surfaces:

- PTFE

Polypropylene

PVC

Epoxy

Viton

Polyester - O-Ring Material:

- Perfluoroelastomer (contact factory for current compound)

- Recommended Filtration:

- 20 microns or less

- Compatible Liquids:

- Low viscosity (<10 cS)

Minimum amount of entrained air - Warm-Up Time:

- None

- Zero Drift:

- PTFE Sapphire

- Calibration Interval:

- Calibration should typically be verified once every 12 months

- Power Requirements:

- 22-25 VDC

250 mA typical (1 A peak) - Electrical Connections:

- 7-pin connector

PTFE housing when used with CFx cables

Nylon housing when used with CPx cables - Typical Response Time:

- Typically <3 seconds to 97% of final value

- Reliability:

- 100,000 Hours MTBF (testing ongoing)

- Approvals/Certifications:

- CE Approved

89/336/EEC (EN 55011 & EN 50082-1)

73/23/EEC Low Voltage Directive - Ratings:

- IP64 (NEMA 4X)

- Warranty:

- 1 year limited

- 0-10 VDC Output:

- 0 VDC at zero flow

5 Kohm or greater output load

Not isolated - 4-20 mA Output:

- 4 mA at zero flow

500 ohm maximum current loop

Not isolated - 0-5 VDC Output:

- 0 VDC at zero flow

2.5 Kohm or greater output load

Not isolated - 0-10 VDC Input:

- 0 VDC at zero flow Input load is 100 Kohms Isolated from ground

- 0-5 VDC Input:

- 0 VDC at zero flow Input load is 100 Kohms Isolated from ground

- 4-20 mA Input:

- 4 mA at zero flow Input load is less than 50 ohms Isolated from ground

- Error Output:

- Activated when controller cannot achieve setpoint

Error condition=high (V+)

Normal condition=low

Automatically resets upon normal condition

Typical delay before activated: 8-10 seconds - Standby Mode:

- Disables valve (freezes)

Automatically engaged when setpoint is <5% of full scale

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|