McMillan thermal products are capable of measuring gases or liquids in line sizes 1/2″ or smaller. Because of the compact size and affordable cost of these products, thermal products are suitable for a wide variety of industrial, commercial, laboratory and OEM applications. Thermal mass flow meters feature fast response, virtually zero maintenance, and precise measurement.

McMillan incorporates multiple versions of thermal sensing technology, including:

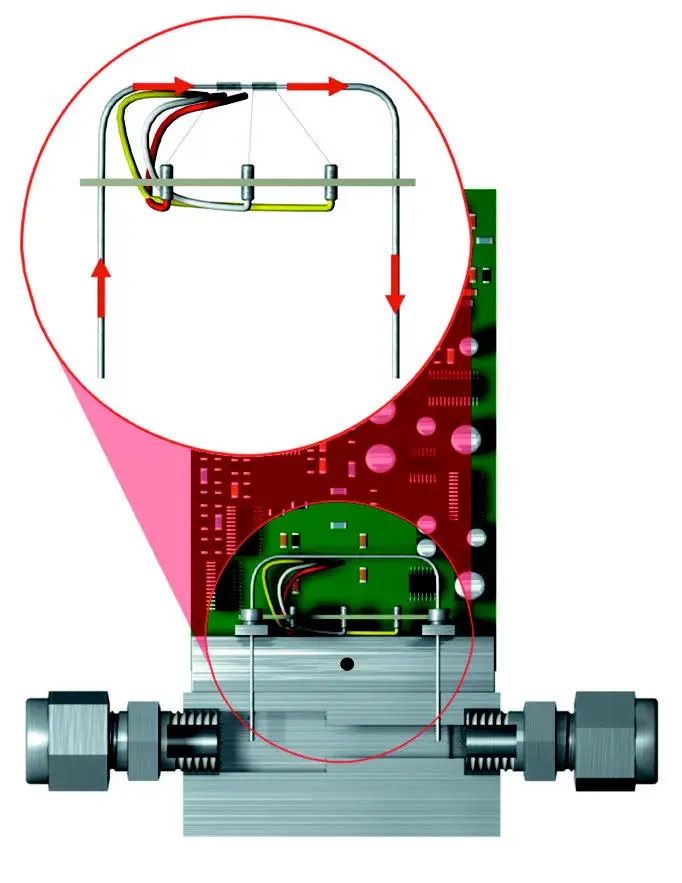

A portion of the flow entering the device is re-directed into a small tube. This tube is heated to a default constant temperature with a set of precision wound thermal coils. As gas flows through the tube, heat is transferred from the tube and into the flowing gas, cooling the tube in the process. The thermal coils must increase power to bring the now cooling tube back to the default constant temperature. This increase in power is measured and used to calculate mass flow. McMillan’s proprietary system ensures that the zero (default constant) remains stable and the sensor is extremely repeatable.

The output of the thermal mass flow sensor is directly related to the specific heat characteristic of the gas being measured. Therefore, if a unit is calibrated for air, it is relatively simple to calculate a correction for nitrogen or other similar gases. This advantage offers flexibility not found with many other sensing technologies.

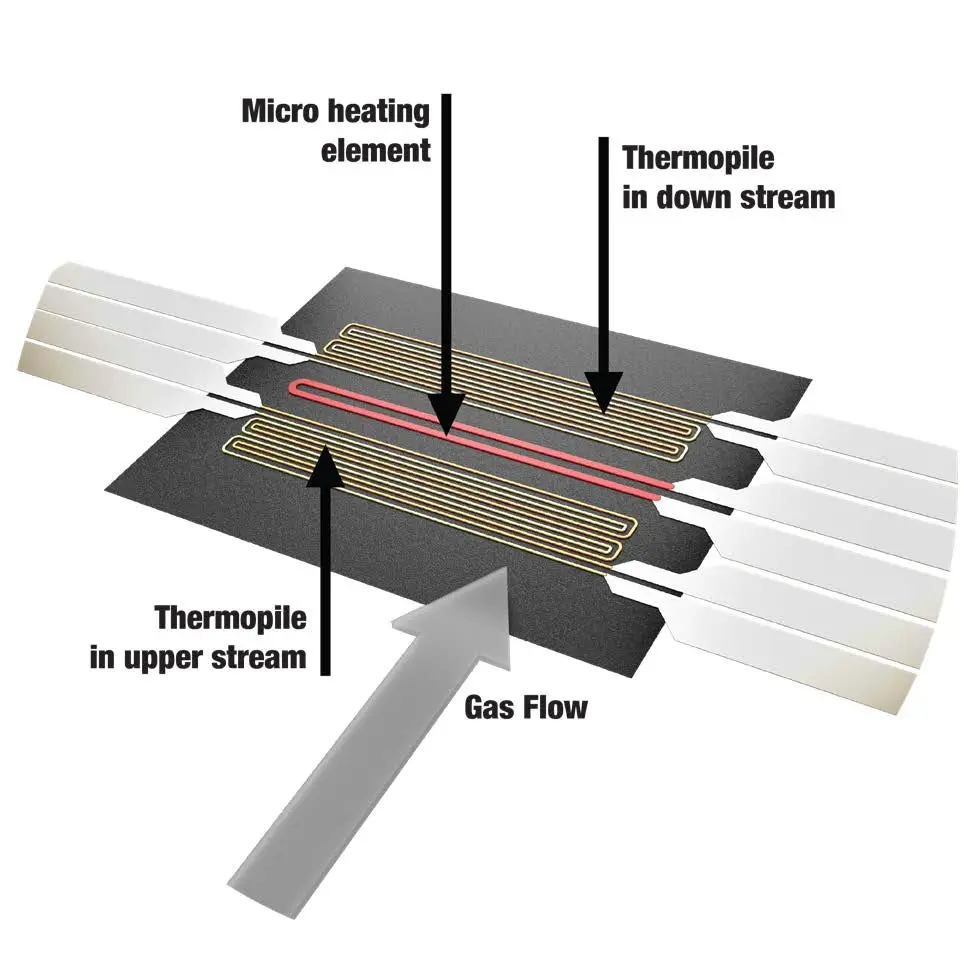

This technology, often referred to as MEMS, provides fast response, virtually zero maintenance, and precise measurement.

MEMS technology utilizes a compact, reliable CMOS (Complementary Metal Oxide Semiconductor) sensor. This no-drift sensor module is comprised of both the electronic and mechanical elements on a single silicon chip, similar to the process used for integrated circuits.

Flow enters the unit, and a portion of the flow is redirected into a chamber and across the MEMS device. This device has two temperature sensors, one downstream from the other. Between the coils sits a small heating element, as shown in the illustration. As the gas passes through the device, the smart electronics sense the difference in heat between the two sensors, since the upstream coil is not exposed to the heated gas. The downstream coil senses the heated gas and McMillan’s advanced sensing algorithm calculates the flow rate based on the difference in value.

The precision manufacturing and compact size of the MEMS device ensure that the zero remains stable and the sensor is extremely repeatable.

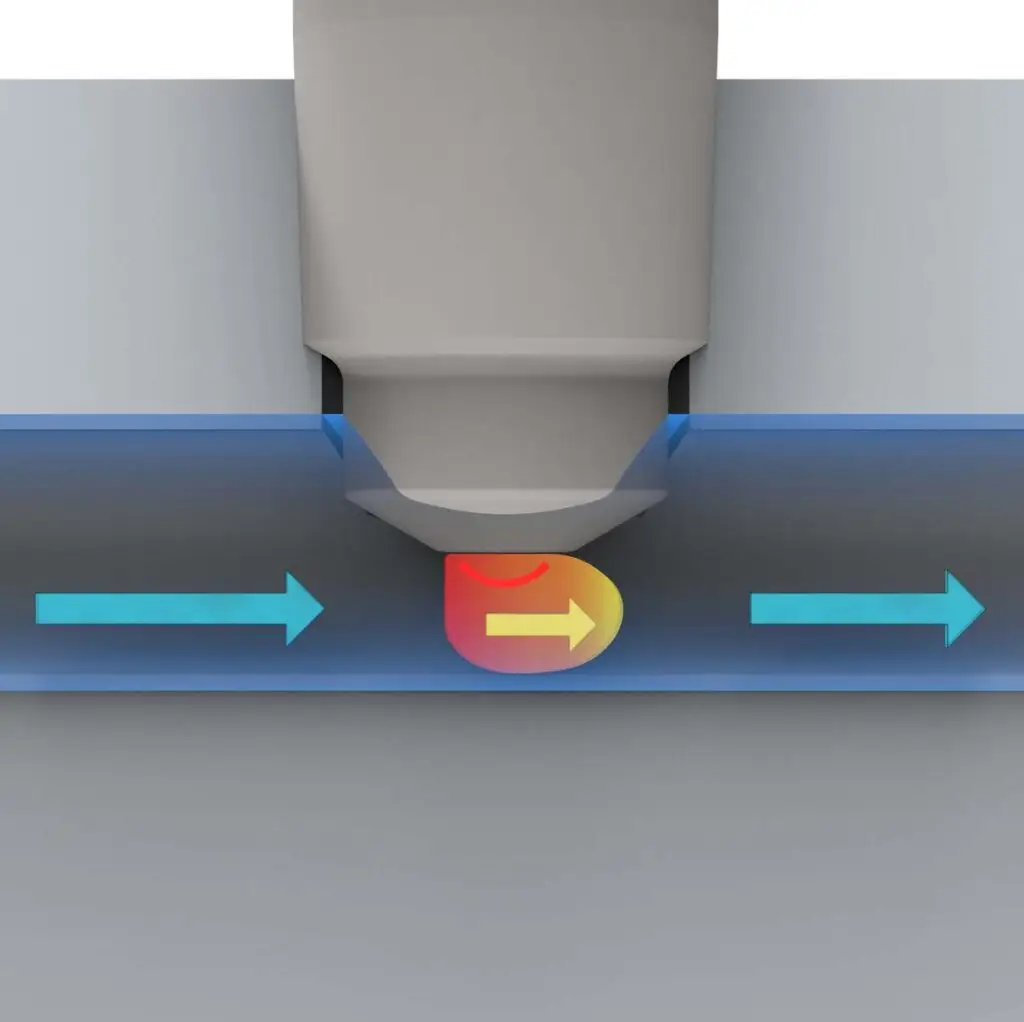

Thermal probe technology utilizes the calorimetric principle to monitor liquid flow. The device’s sensor tip is heated to a few degrees above the liquid temperature (as shown in red in the illustration). As liquid flows across the tip (as shown in blue arrows), heat is carried away (as shown with the yellow arrow), cooling the sensor in the process. The amount of cooling is proportional to the liquid’s velocity. The monitored flow is then compared to a programmed setpoint, which is field-adjustable by the user. A transistor switch is activated when the flow setpoint is reached.

The thermal flow switch is integrated into an engineered flow body that helps ensure optimal flow conditions are met. Design elements allow for a fully developed flow profile to be achieved, aiding the sensor in making the most accurate measurement possible. This engineered flow body makes installation quick and cost effective while ensuring reliable results for the customer.

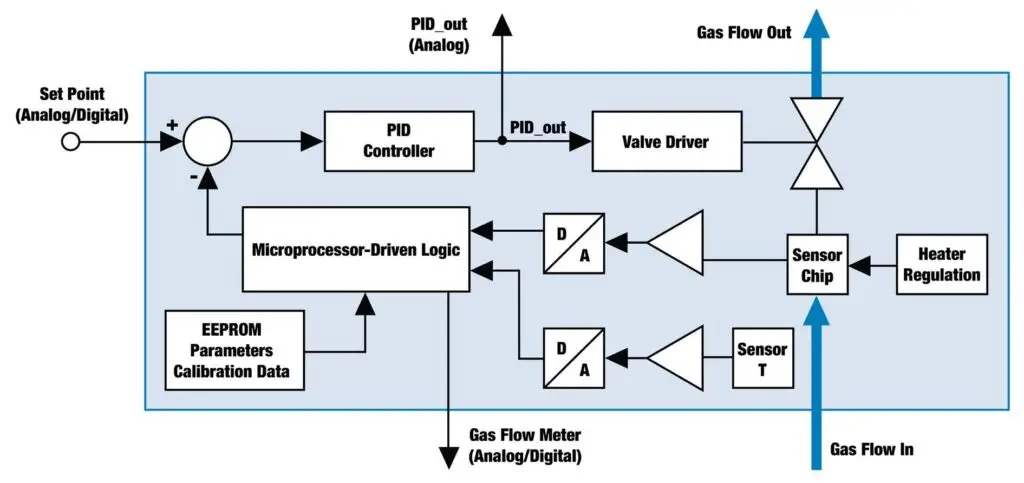

Flow passes from the flow sensor into the proportional solenoid valve. This valve is controlled by the active servo electronics, which compare a setpoint (supplied via analog input signal) to the actual flow rate provided by the flow sensor and adjust the valve accordingly.

A flow chart of the flow controller logic is provided as an illustration.

We are experts in all things flow. As a company founded and run by engineers, we seek to understand your application and then build a product solution that will solve your most difficult challenges.

McMillan Flow sales agents are strategically located across the

globe. Find your nearest distributor or office.

McMillan Company

7075 Ranch Rd 2338

Georgetown, TX 78633

sales@mcmflow.com

Phone: (844) MCM-FLOW

Copyright © 2025 McMillan Flow Products. All Rights Reserved.

McMillan Flow Products is located in the U.S.A. and all products are manufactured in our Texas plant.

"*" indicates required fields